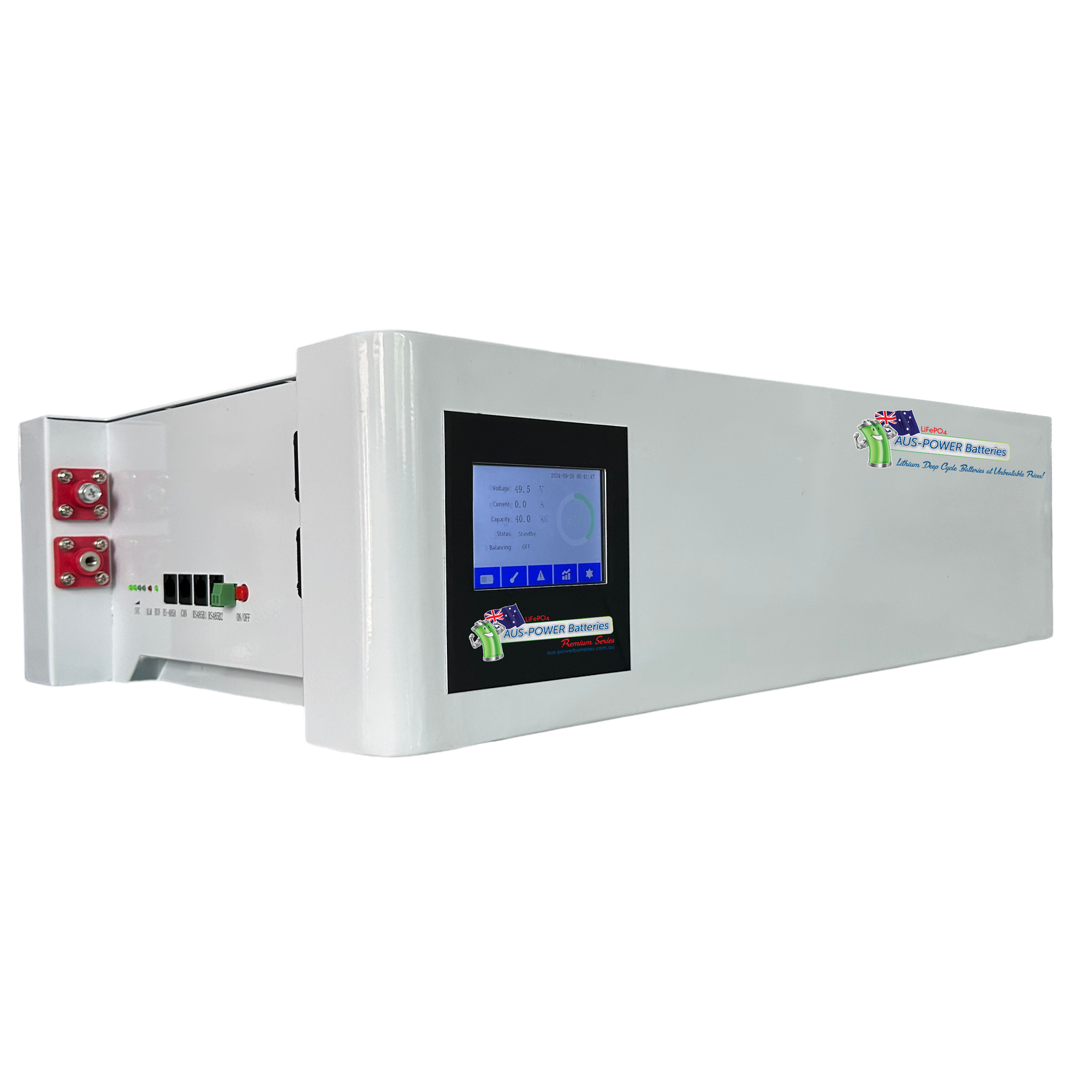

Introducing Lithium Iron Phosphate (LiFePO4)

The Gold Standard Chemistry For Battery Storage Solutions

Like all things, batteries come in different varieties.

The chemistry used within these batteries varies from one brand or model to another, so buyers need to be aware of what they are actually purchasing and if that technology and those specifications are best suited for their intended purpose.

Until recently most battery technologies were based upon Lead-Acid technology, a technology that hasn’t really advanced much in over 100 years.

In more recent years Lithium-Ion batteries became popular due to their increased capacity, higher levels of discharge, and longer life cycles.

Today that too is old technology and Lithium LiFePO4 batteries (Lithium Iron Phosphate) have become the gold standard for battery storage solutions, offering greater charge and discharge rates, longer life cycles, and much greater safety (less chance of self-combustion), and are also much more friendly towards the environment.

Our Manufacturing Process

See for yourself why our products are superior

We are so confident in the quality of our products, that we proudly show you inside the battery and how our batteries are constructed, something other vendors are reluctant to do, which leads to the question WHY?

Step 1 - Sourcing the Cells

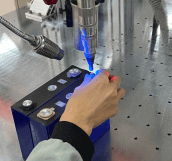

Step 2: Matching, Laser Welding & Studs

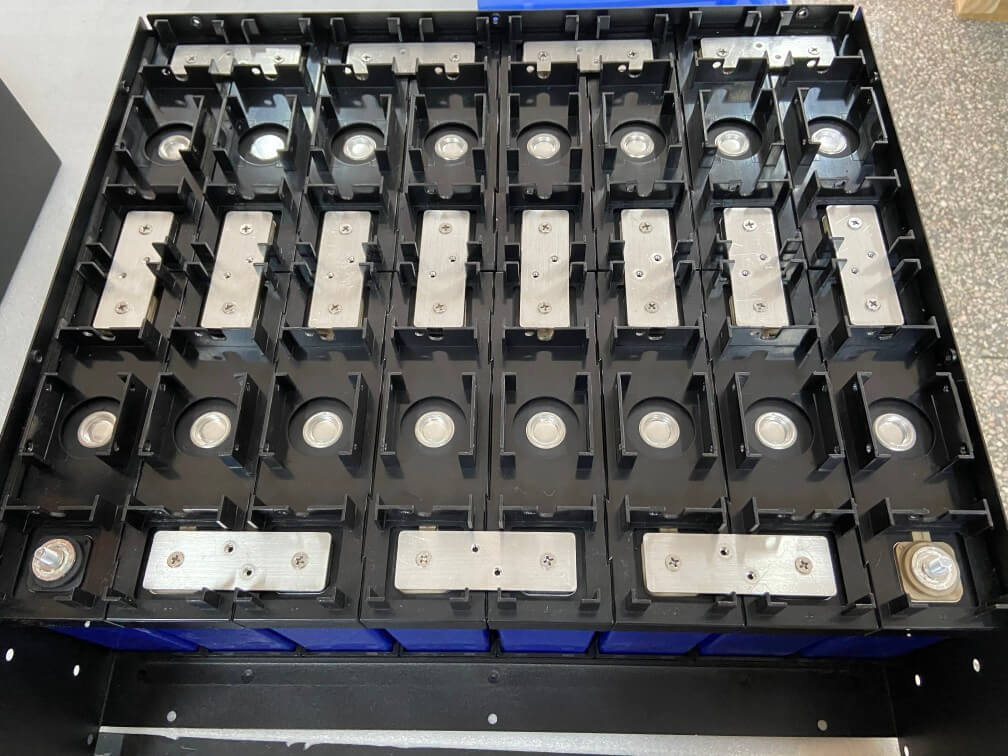

Step 3: Pre- Assembly

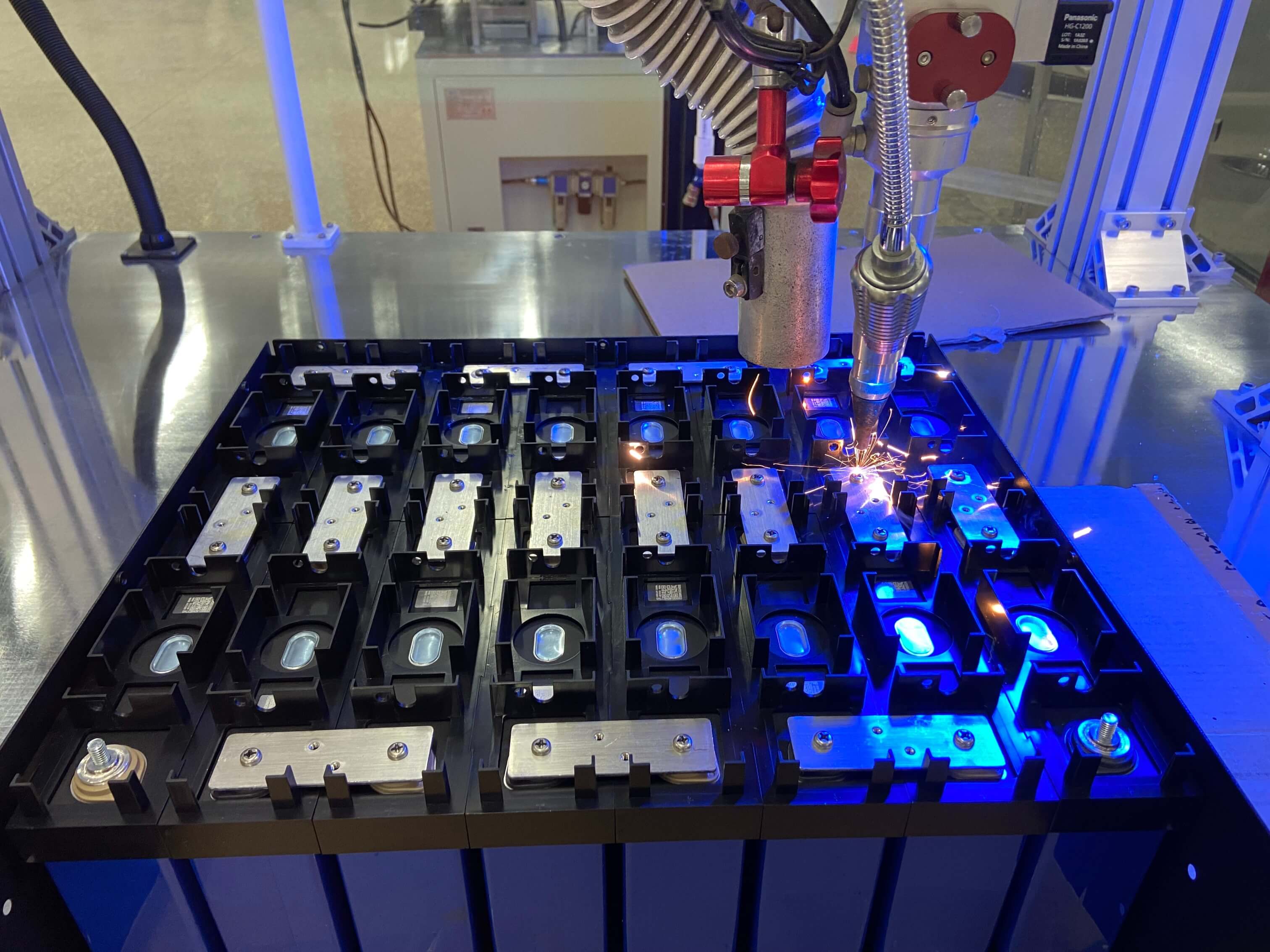

Step 4: Laser Welding Bus Bar Connections

Step 5: Installation of BMS & Pre-Charge Resistor

Step 6: Cables, Balance Leads & Temperature Sensors are installed