Introducing Lithium Iron Phosphate (LiFePO4)

The Gold Standard Chemistry For Wall Mounted Batteries

AUS-POWER Batteries Premium Series Wall Mounted Batteries are purpose-built for off-grid systems and Energy Storage Solutions where floor space is limited. Designed to mount directly on a wall, they free up valuable ground space while still delivering the same high performance and reliability as our rack-mounted and stackable options. This makes them a great choice for homes, sheds, or installations where a compact footprint is essential.

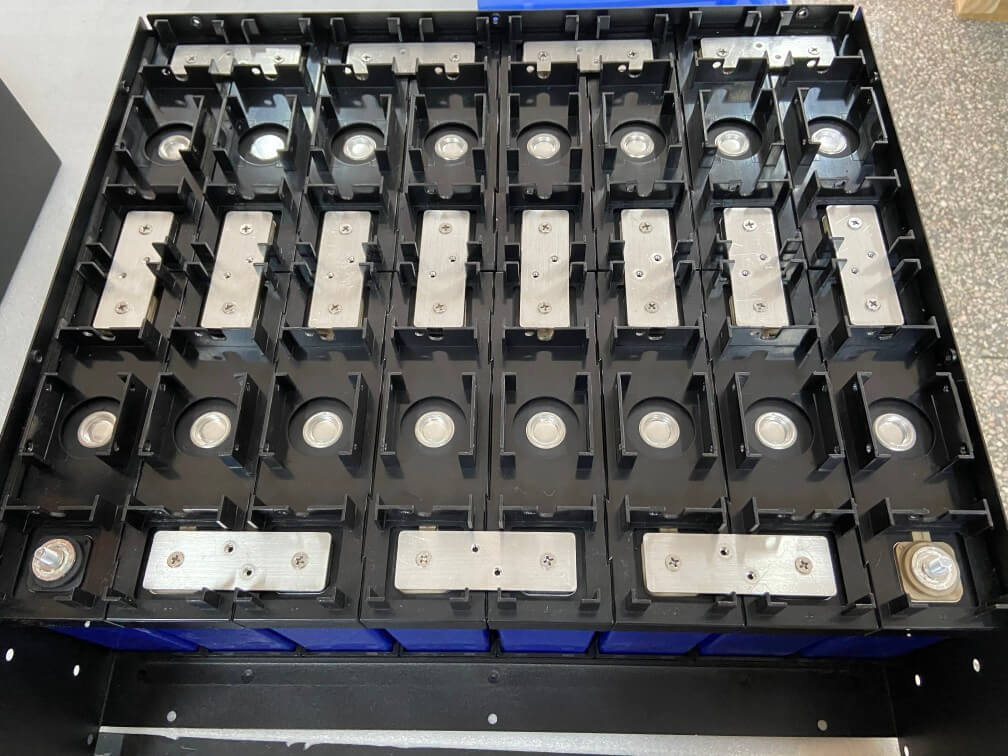

Each 5kWh LiFePO4 battery module is built using 16 x A-Grade prismatic cells that are matched, balanced, and laser-welded for durability. An industrial-quality Battery Management System (BMS) is integrated into every unit, constantly monitoring voltage, current, temperature, and cell balance to ensure maximum safety and performance.

Like the rest of the AUS-POWER Premium Series, our wall-mounted batteries feature a modular design, meaning capacity can be expanded as your energy needs increase. Their slimline format doesn’t compromise on strength or functionality, offering the same robust protections and advanced features found across our range.

Key Benefits

Space-saving wall-mounted design – minimal footprint for tight installations

Designed by Australian off-grid specialists with over a decade of first-hand lived experience

3A active balancer to keep cells precisely balanced and extend battery life

Heavy-duty build with 200A terminals, 35mm cables included, and laser-welded connections

Smart monitoring via colour touch screen and master unit oversight

Seamless integration with most major inverter brands (open or closed loop)

Quick installation with automatic dip switch assignment

Backed by a 10-year warranty

AUS-POWER’s Premium Series Wall Mounted Batteries provide a reliable, expandable, and space-efficient energy storage solution—ideal for anyone needing dependable off-grid or ESS power without compromising on room.

Wall Mounted Batteries

Our Manufacturing Process

See for yourself why our products are superior

We are so confident in the quality of our products, that we proudly show you inside the battery and how our batteries are constructed, something other vendors are reluctant to do, which leads to the question WHY?

Step 1 - Sourcing the Cells

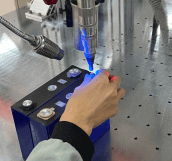

Step 2: Matching, Laser Welding & Studs

Step 3: Pre- Assembly

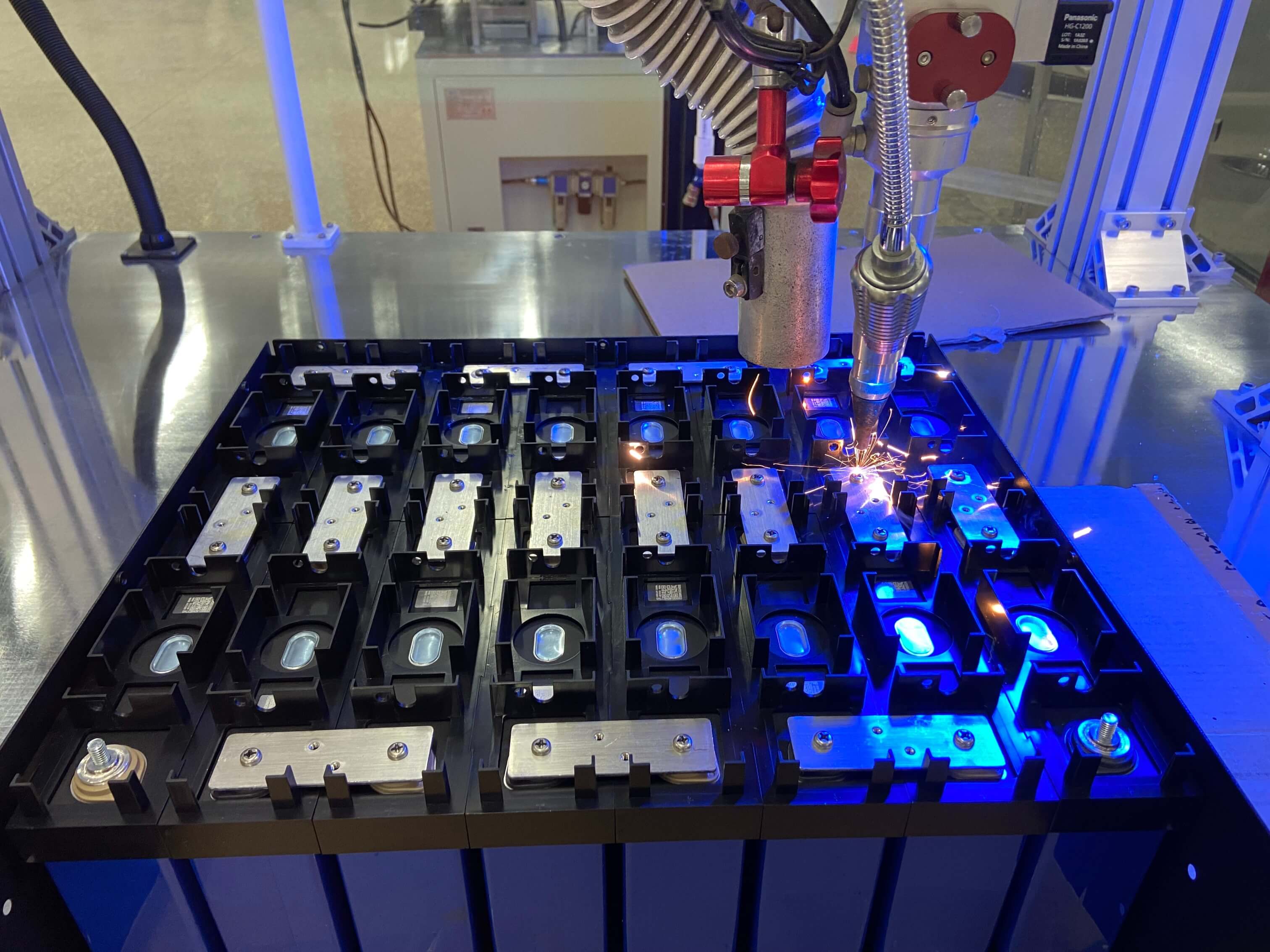

Step 4: Laser Welding Bus Bar Connections

Step 5: Installation of BMS & Pre-Charge Resistor

Step 6: Cables, Balance Leads & Temperature Sensors are installed

Step 7: Final Assembly, Testing & Packaging Ready For Dispatch

Speak to an off-grid battery expert today!

Whether you’re ready to buy your battery or just want to better understand your options, enquire now. We’ll take the time to discuss your goals and provide a customised off-grid battery solution you can rely on.